THE ORIGINS OF RESL

Reverse Engineering Services Limited (RESL) is a global business which is unique in that it specializes 100% in decommissioning and has worked continuously in decommissioning and well abandonment for over 30 years.

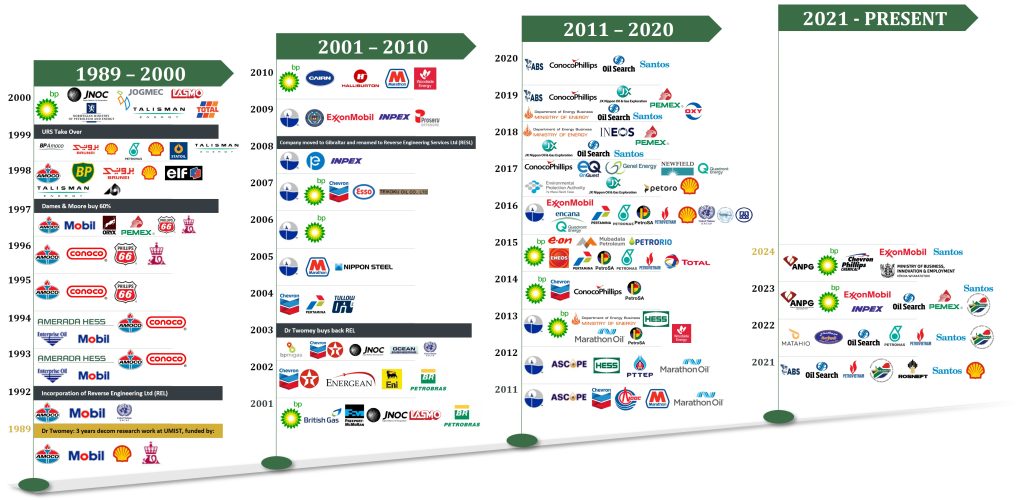

Reverse Engineering Services Limited (formerly known as Reverse Engineering Limited) has been continuously working on decommissioning for over 30 years. The company was incorporated as Reverse Engineering Ltd (REL) in 1992 following a 3-year research program at UMIST in Manchester, UK by current Managing Director of RESL, Dr. Brian Twomey, funded by BP, Amoco, Shell and the Norwegian Petroleum Directorate.

Following work for major oil companies like Amoco, Conoco, Mobil, Enterprise, Amerada Hess, Phillips etc., Dames & Moore acquired 60% of the company in 1997. In 1999, the company was taken over by URS. Dr. Brian Twomey bought back the company in 2004. In 2008, the company was renamed Reverse Engineering Services Ltd and moved to Gibraltar. Following working for international companies in the petroleum industry for decades, the company has experienced a step-change in activity level recently and is now working for multiple stakeholders globally.

To date RESL has completed decommissioning work on over 870 facilities, more than 1,876 well P&A’s, numerous pipelines and subsea systems, over 22 FPSO & FSO facilities, over 40 onshore facilities for most of the major oil & gas companies worldwide. RESL has worked for major oil and gas operators around the world, including Australia, UK, Norway, Netherlands, Greece, Canada, Gulf of Mexico, Japan, Indonesia, India, South Africa, Thailand, Tanzania, Nigeria, Cameroon, Chad, Brazil, Australia, East Timor, New Zealand, West Coast & GOM USA, South Africa, Brunei, Myanmar and Malaysia etc.

RESL have carried out peer reviews of decommissioning projects, decommissioning studies, engineered the removal of offshore structures, cost analysis for decommissioning accruals, managed decommissioning technology development of joint industry projects, acted as expert witnesses in decommissioning cost disputes and been involved in the post decommissioning analysis of removals in the Gulf of Mexico and the North Sea. Many of previous RESL studies have included socioeconomic impact analyses, cost/benefit assessment and decision analysis methodology.

Through the company’s 30 year decommissioning history, a proven track record with repeat customers has been developed. Our decommissioning experience comes from working globally with stakeholders ranging from super majors to small independents, as well as governments, regulators, contractors, international agencies, law firms, insurance companies and investment banks.

RESL provides support its clients worldwide in planning use our unique decommissioning process from conceptual planning through to completion. During this journey all options are considered, evaluated, balanced and ranked so a full systematic audit trail remains. This proven methodical decommissioning approach minimizes unwanted surprises offshore and onshore. The decommissioning of onshore installations, offshore installations, subsea installations, templates, flow lines umbilical’s, pipelines and wells etc. is a complex multi-discipline exercise where cost accuracy has often proved elusive.

The major challenge is trying to find the right balance between often-conflicting drivers:

- Health & Safety

- Environmental

- Law & Regulation

- Technical Feasibility

- Cost

- Disposal & Recycling

- Public Perception

The decommissioning requires much pre-planning. As a rule-of-thumb the decommissioning planning of a medium size offshore platform should begin a minimum of four years before the projected removal date. In countries with complex regulatory and permitting regimes the decommissioning planning should start even earlier. Detailed planning, early identification of possible decommissioning “hot-spots” and planning of operational alternatives in the higher risk areas will reduce and minimise expensive offshore delays and mistakes.